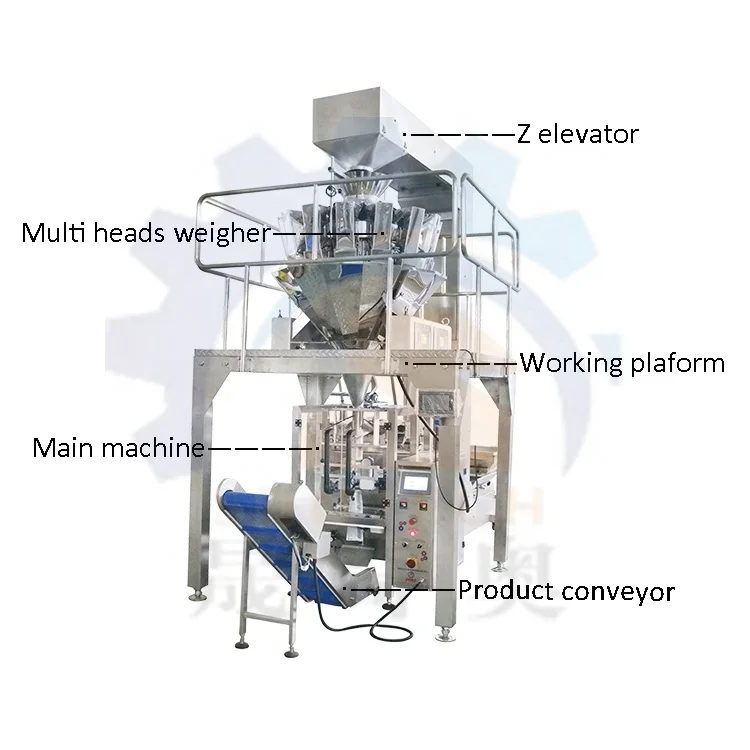

Product Description of Frozen Food Packaging Machine

It is suitable to use in packing the high accuracy and easy fragile material. Such as: puffy food,chips, jelly, candy, pistachio nuts, nuts, apple slices, frozen dumpling, coffee beans, pasta,cotton candy, french fries, rice, pet food, small hardwares, etc.

|

Model

|

SUN-320 |

SUN-420 |

SUN-520 |

SUN-720 |

|

Packing Speed

|

5-60 Bags/Min

|

|

Volume(ML)

|

800

|

1000

|

2000

|

5000

|

|

Bag Width(MM)

|

50-150

|

60-200

|

80-250

|

150-350

|

|

Bag Length(MM)

|

80-200

|

80-300

|

80-400

|

80-450

|

|

Max Width Of Roll Film(MM)

|

320

|

420

|

520

|

720

|

|

Thickness

|

0.04-0.09 MM

|

|

Material

|

OPP/CPP PET/PE PET-AL/PE Lamination Film

|

|

Weight(KG)

|

350KG

|

450KG

|

550KG

|

750KG

|

|

Air Consumption

|

0.65Mpa 0.3m³/Min

|

0.65Mpa 0.4 m³/Min

|

0.8Mpa 0.4m³/Min |

0.8Mpa 0.4m³/Min

|

|

Power Supply(KW)

|

2.2

|

2.2

|

2.2

|

3.0

|

|

Dimension LxWxH(MM)

|

1170X820X1285 |

1320X920X1392 |

1500X1140X1540 |

1800x1250x1780 |

|

Temperature Precision

|

±1℃

|

|

Weighing Precision

|

±0.5~±2.0g |

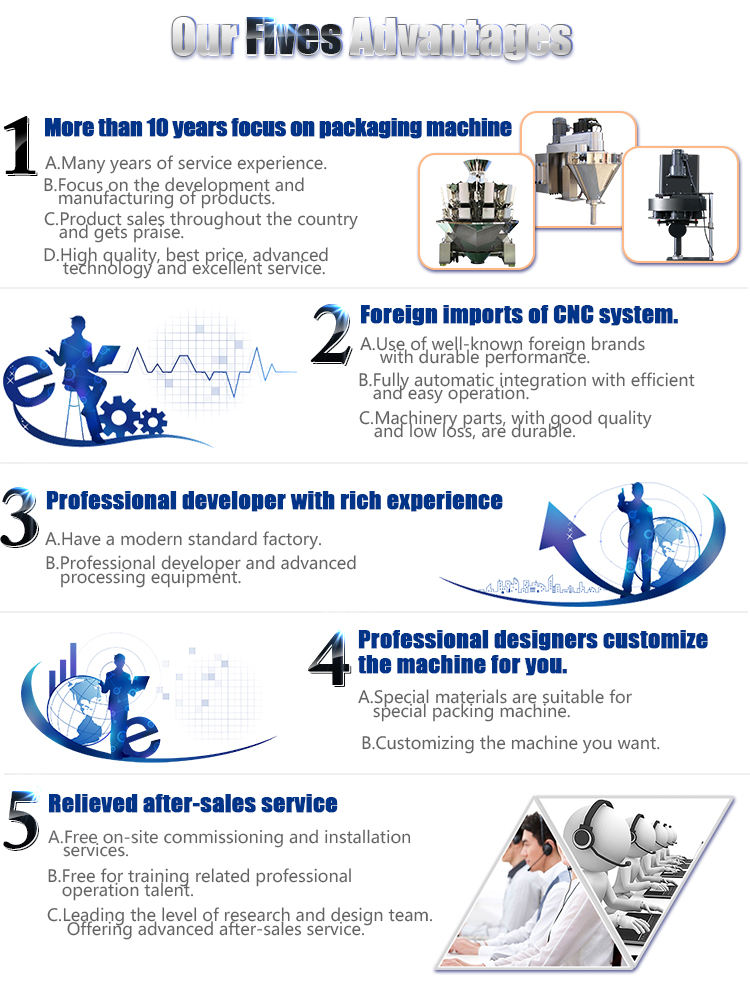

Our affordable, easy to use packaging machine are suitable for company wanting to automate their packaging processes for the first time or to the larger producer looking for more productivity and efficiency.

How to Delivery

We use non fumigation pallets plywood cases to pack machines.

Our Service

✔ Pre-Sale Service:

We will according your product feature, weight of each bag, and shape of bag make a quotation for you. Then more details we need communication such as material and thickness of film, dimension of bag you already have it or need we design for you, Operate language,what kind of voltage at the local.

✔ After-Sale Service:

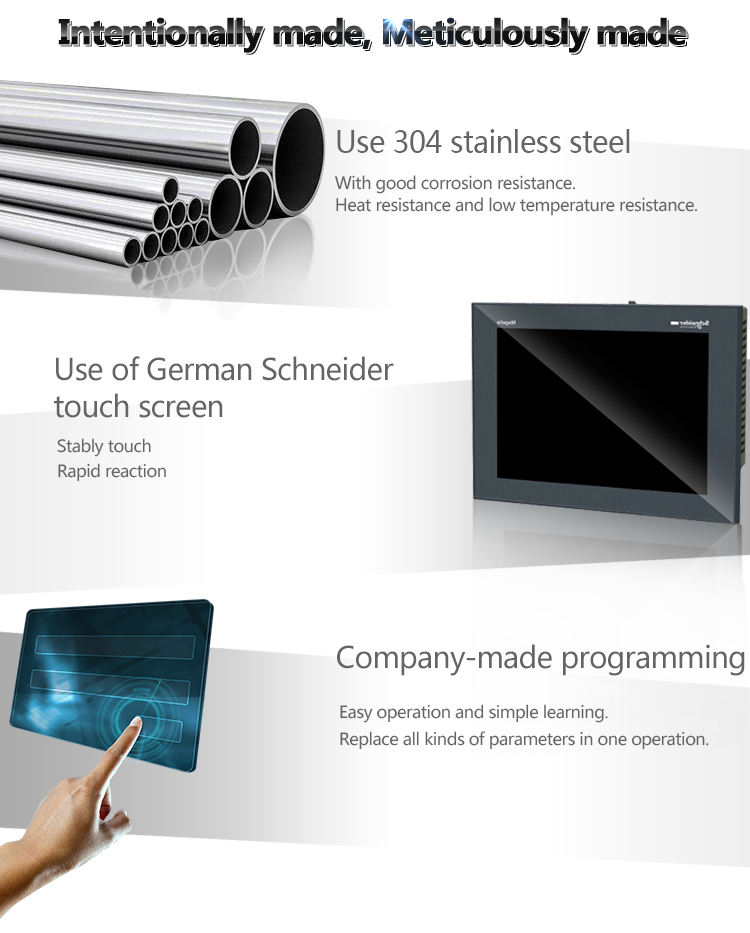

Warranty: 2 Years except wearing parts ( Cutter, Belt, Horizontal and vertical Heating Tube etc), Most of components are free-replacement (PLC, Servo controller, Servo motor, Touch screen, Cylinder). Machine delivery will with a tool box, there have some parts are free.

Operation training:

1: Machine is very easy operate, delivery with manual, offer lots of photos and videos when machine in assembling or disassembling.

2: Welcome to our factory learning.

3: Engineers available to service machinery overseas.

About Suntech

We has gained rich experience in the packing machinery field and has many mature technologies. So far, dozens of packaging machine series have been successfully developed to achieve the optimal matching of automatic weighing machines and packaging machines. It is widely used in Food, Beverage, Pharmaceutical ,Chemical, Hardware accessories and other industries. It is the preferred equipment to achieve production automation and improve production efficiency. At present, the products are exported to Europe, America, Middle East, Southeast Asia, Africa and other parts of the world, and are deeply trusted and praised by users.

We not only provide customers with high quality and reliable products, but also design and manufacture packaging equipment according to customers' actual requirements, provide packaging overall solutions, undertake various standard packaging machines OEM business, and provide professional technical service support for customers. To create greater value for customers.

"Strictly Abide by the Integrity, the Pursuit of Excellence", all the Suntech people must take it as their conviction and serve the customers wholeheartedly, warmly welcome customers at home and abroad to visit and guide, we hope to create brilliant success together with you!

Certifications

How Do Frozen Food Packaging Machines Work?

Frozen Food Packaging Machines are specialized packaging equipment used for packaging frozen food products. The exact operation of these machines can vary depending on the specific type of machine being used, but the general process typically involves the following steps:

●Feeding the product: The frozen food product is fed into the machine either manually or automatically, depending on the packing machine.

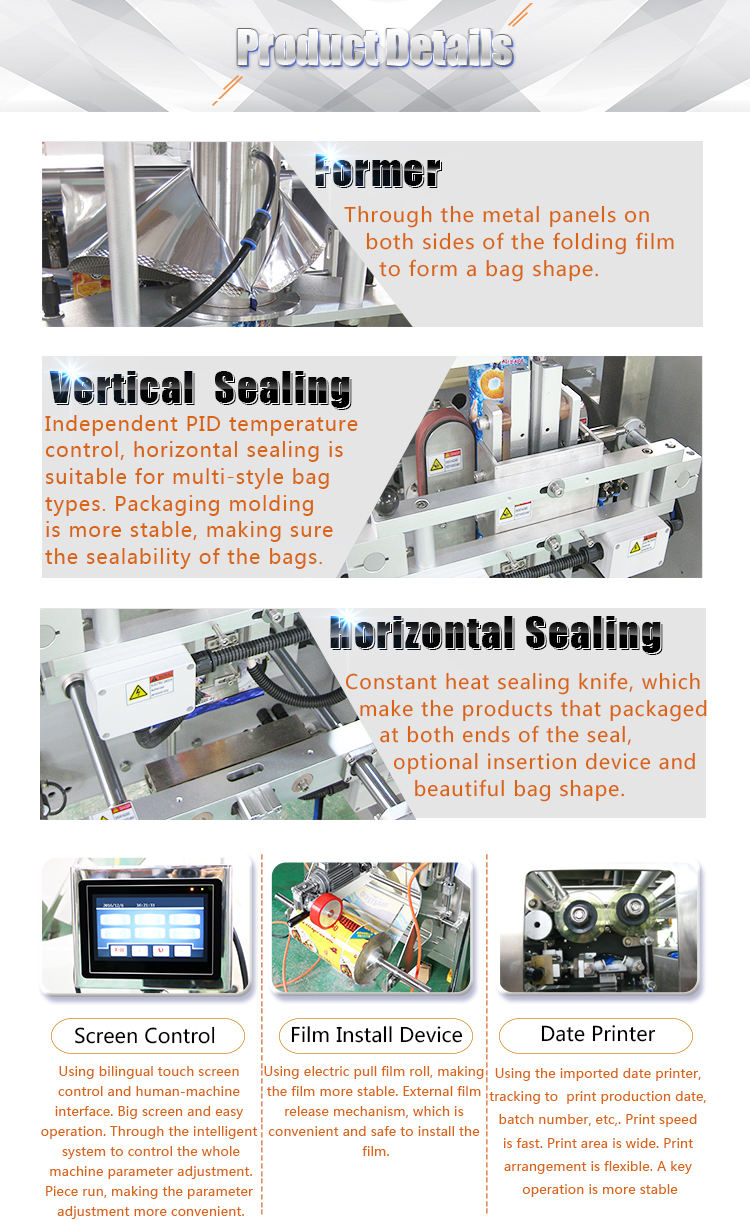

●Forming the package: The packaging material, such as plastic film or foil, is formed into the appropriate shape and size to fit the product being packaged. This is typically done using rollers or other shaping mechanisms.

●Filling the package: The product is then deposited into the packaging material. This can be done using a variety of mechanisms, such as augers, pistons, or weighers.

●Sealing the package: The packaging material is sealed around the product, typically using heat, pressure, or a combination of the two. This creates an airtight seal that helps to preserve the quality and freshness of frozen food.

●Cutting and separating the packages: Once the package is sealed, it is cut and separated from the rest of the packaging material. The exact method of cutting and separating can vary depending on the type of machine being used.

Overall, Frozen Food Packaging Machines are designed to automate the packaging process for frozen foods, increasing efficiency and reducing labor costs. By using specialized packing machinery to form, fill, and seal packaging around the product, these machines can help to ensure that frozen foods are properly packaged for storage and transportation.

What Maintenance is Required for A Frozen Food Packaging Machine?

To ensure the optimal performance and longevity of a Frozen Food Packaging Machine, regular maintenance is required. Here are some of the maintenance tasks that may need to be performed:

●Cleaning: Regular cleaning is essential to keep the machine free of debris and buildup, which can interfere with its operation. The specific cleaning procedures will depend on the type of machine and the type of packaging material being used.

●Lubrication: Moving parts of the machine need to be lubricated periodically to reduce friction and wear. The type of lubricant used will depend on the machine's design and the manufacturer's recommendations.

●Inspection: The machine should be regularly inspected to identify any signs of wear or damage. Worn or damaged parts should be repaired or replaced promptly to avoid further damage to the machine or the packaged product.

●Calibration: Some machines may require periodic calibration to ensure accurate weighing or filling of the product.

●Software updates: If the auto packing machine has a control system or software, regular updates may be required to ensure the machine is running efficiently and to fix any bugs or issues.

It is important to follow the manufacturer's recommended maintenance schedule for the specific machine to ensure its proper operation and to avoid breakdowns or product contamination. Regular maintenance can also help to extend the life of the machine, reduce downtime, and minimize repair costs.